| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : CNSME

Model Number : 6/4D-R

Certification : ISO/CE

Place of Origin : CHINA

MOQ : 1 Set

Price : Neogotiable

Payment Terms : T/T, Western Union

Supply Ability : 20 Sets per Month

Delivery Time : 7 Working Days

Packaging Details : Plywood Crate

Impeller : Natural Rubber

Theory : Centrifugal

Usage : Slurry Pumping

Liners : Rubber

Shaft : Horizontal Type

Color : Blue

Slurry Pump with Natural Rubber Wet End Components used for Acidic Slurry Applications

Introduction:

1. Slurry pumps are devided into metal and rubber lined slurry pumps. Metal pumps and rubber pumps are employed into different applications.

2. Rubber lined slurry pumps are used in below areas:

Mining and Mineral Processing

Power Generation and Steel Plants

Industrial Effluents and Liquors

Coal Preparation and other Acidic Applications

3. Phosphric acid slurry pump SHR/100D is identical to the standard World War-man model 6/4D-R. The material of wear parts is natural rubber-soft black rubber, to resist corrosion.

3. Specifications:

| Model | SHR-100D |

| Outlet | 4-inch |

| Capacity | 144-324m3/h |

| TDH | 12-45m |

| Rated Power | 60Kw |

| Speed | 800-1350r/min |

| NPSH | 3-5m |

| Pump Model | S×D (inch) | Allowable Max. Power (kw) | Material | Clear Water Performance | |||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | |||||

| Impeller | m3/h | l/s | |||||||

| SHR/25B | 1.5×1 | 15 | Rubber () | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | |

| SHR/40B | 2×1.5 | 15 | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | |

| SHR/50C | 3×2 | 30 | 36-75.6 | 10-21 | 13-39 | 1300-2100 | 2-4 | ||

| SHR/75C | 4×3 | 30 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | |

| SHR/75D | 4×3 | 60 | |||||||

| SHR/100D | 6×4 | 60 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | |

| SHR/100E | 6×4 | 120 | |||||||

| SHR/150E | 8×6 | 120 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | |

| SHR/150F | 8×6 | 260 | |||||||

| SHR/150R | 8×6 | 300 | |||||||

| SHR/200F | 10×8 | 260 | 540-1188 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | |

| SHR/200ST | 10×8 | 560 | 540-1188 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | |

| SHR/250F | 12×10 | 260 | 720-1620 | 320-700 | 13-14 | 300-500 | 79 | 3-8 | |

| SHR/250ST | 12×10 | 560 | 720-1620 | 320-700 | 13-14 | 300-500 | 79 | 3-8 | |

| SHR/300F | 14×12 | 260 | 1152-2520 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | |

| SHR/300ST | 14×12 | 560 | 1152-2520 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | |

4. Photos shipped to Worldwide

5. SHR/100D: SHR --- SME Heavy Rubber Pump; 100 --- 100mm (4-inch), Outlet; D --- Frame Type, bearing a maximum of 60Kw motor.

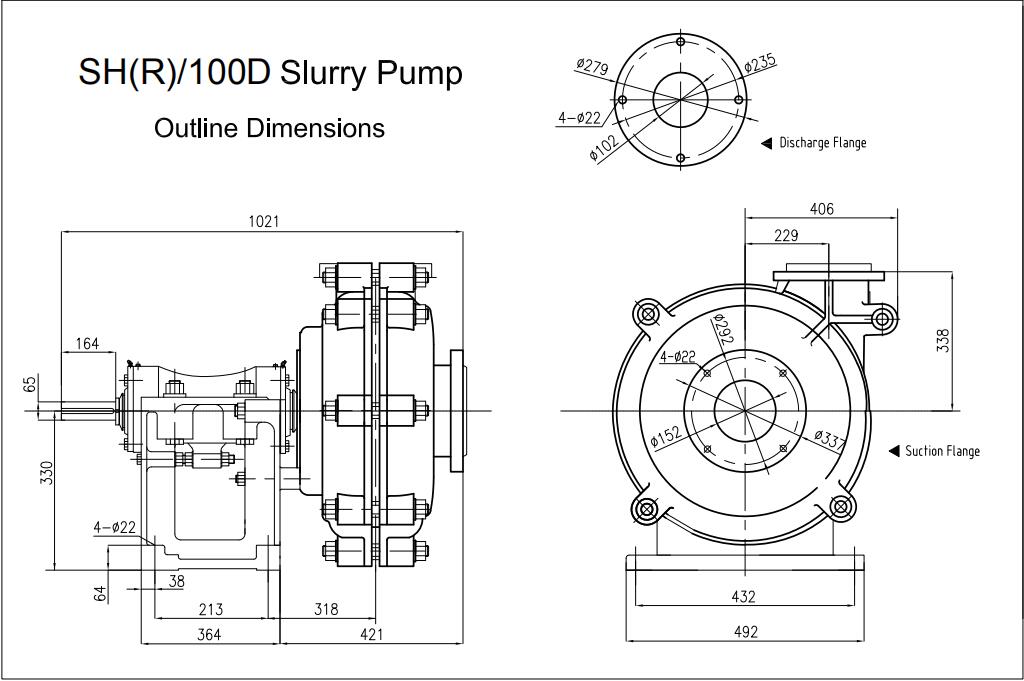

6. Outline Dimensional Drawing:

Construction of Rubber Slurry Pump:

Typical Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Corrosive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

Standard Material of Wet-end Parts: Natural Rubber

Performance Curve:

|

|

Natural Rubber Centrifugal Slurry Pump Wet End Components for Acidic Slurry Applications Images |